Review about Shafiq Wood Products Trading from Begum Monty

When booking to request for customizing wood products it was easy. Their staff will reach you through calls and will do the needful action once you stated your wood requirements. The wood quality during the inspection of my order is great! It was the same as the sample they provided to me. The services are also fast and efficient. The transaction is also smooth no error has occurred.

Shafiq Wood Products Trading

- Mon

- 08:00 AM - 06:00 PM

- Tue

- 08:00 AM - 06:00 PM

- Wed

- 08:00 AM - 06:00 PM

- Thu

- 08:00 AM - 06:00 PM

- Fri

- Closed

- Sat

- 08:00 AM - 06:00 PM

- Sun

- 08:00 AM - 06:00 PM

Services:

Flooring / Accessories; Payment methods: Cash payment, Bank cheques; Service Language: English, Hindi, Urdu.

Woodworking supply store in Ajman

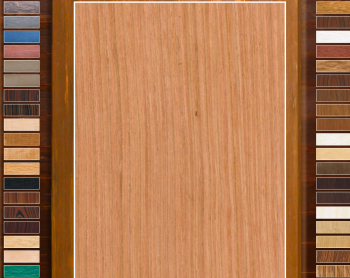

WOOD VENEERS WITH EXOTIC LOOKS AND PERFECTION IN COLOUR AND DESIGN.

IPIR-ITALY BURLS WOOD VENEERS AND SEVERAL OTHER PRECOMPOUND WOOD VENEERS ARE FSC® CERTIFIED (FSC®-C135839). ASK ABOUT OUR FSC®-CERTIFIED PRODUCTS. WE ARE MARKETING RECOMPOSED WOOD VENEERS OF TOP GRADE MANUFACTURED BY MESSERS; F.LLI ZANGHERI AND C .S.R.L. ITALY FOR LAST MORE THAN 32 YEARS IN PAKISTAN MARKET AND FOR MORE THAN 14 YEARS IN G.C.C. MARKET.

PRODUCTION PROCESS IN BRIEF IS AS FOLLOWS; TOP QUALITY LOGS OF AYOUS , ITALIAN POPULAR AND OTHER SPECIES AS DETERMINED DEPENDING ON END PRODUCT ARE FIRST ROTARY PEELED INTO VENEER. THEN ONLY GOOD QUALITY VENEER IS SELECTED ON AUTOMATED MACHINES AND ALL SUB-STANDARD VENEER IS DISPOSED OFF FOR LOWER VALUE USES AND NOT SELECTED FOR PRODUCTION OF RECOMPOSED WOOD VENEERS. ANY HOLES \ OPEN KNOTS \ CLEAR DEFECTS WITHIN SHEETS ARE CLIPPED AWAY AS WASTE.

NOW STARTING WITH ONLY BEST QUALITY OF WOOD VENEERS , THE VENEERS GO TO ELECTRONIC CONTROLLED DRYER. THEN HIGH QUALITY OF DYES FROM EUROPE ARE USED WITH STEAM COMPLETELY COMPUTER CONTROLLED FOR DYEING OF VENEERS INSIDE OUT – REMEMBER QUALITY OF DYES AND PROCESS INVOLVED DETERMINES QUALITY AND LONG LASTING OF RECOMPOSED WOOD VENEERS – SOME CHEAPER PRODUCTS IN THE MARKET USING CHEAPER DYES AND NOT HAVING ADVANCED TECHNOLOGY WILL YIELD INFERIOR QUALITY OF PRODUCT.

THIS DYEING BY STEAM PROCESS MAKES THE WOOD VENEER SOFTER AND EASY TO USE FOR JOINERY FACTORIES, VENEERING FACTORIES AND ALL END USERS.

NOW AFTER ONE OR SEVERAL DYE BATHS DEPENDING ON FINAL PRODUCT, DYED WOOD VENEERS ARE THEN ARRANGED FOR PRESSING WITH MOULDS UNDER CONTROLLED TEMPERATURES AND VERY HIGH PRESSURE PRESSING WITH TOP GRADE OF EUROPE ORIGIN GLUES.PRESSING CYCLE MAY BE ONCE OR SEVERAL TIMES DEPENDING ON END PRODUCT.

ONCE RECOMPOSED BLOCK IS READY, IT CAN BE SLICED AT THICKNESS AS DESIRED BY CUSTOMER WITHIN SOME LIMITATIONS.

STANDARD LENGTHS FOR BURLS VENEERS AND FEW OTHER PRODUCTS IS 250 CMS AND FOR SEVERAL OTHER PRODUCTS STANDARD LENGTHS ARE 220 CMS , 250 CMS , 280 CMS , 310 CMS AND 340 CMS.

NORMAL WIDTHS ARE FROM 64 CMS UPTO 74 CMS – FOR SOME PRODUCTS UPTO 92 CMS WIDTH IS POSSIBLE. IN VERY FEW CASES , SOME PERCENTAGE OF 32 CMS UPTO 38 CMS WIDTH TO BE ACCEPTED BY CUSTOMERS.

BEFORE PACKING, FINAL INSPECTIONS BY EXPERTS ENSURES QUALITY OF THE EXPORT PARCEL IS UPTO THE COMPANY’S STANDARD.

- +971 506286457

- +971 503649417

- +971 6 7480495

- 210, Amman Street, Ajman Industrial 2, Ajman

If you find an error in the description, please let us know!

Comments on the review (0)